How an Eastern PEI hydroponic farm has grown its business to produce flavourful greens and herbs year-round

Hydroponic farming could be called an art, but it’s most definitely a science, and on the south side of Hillsborough River, somewhere between Mt Stewart and Stratford is a 3000-square-foot greenhouse full of fresh plants grown using that science.

Darren Gill, one of the partners of Pure Island Produce, was quick to show me the heart of this operation that grows plants without soil. The technology is a control board with hidden “powers”: regulating UV lights, temperature, as well as CO2, and humidity levels. Another inconspicuous panel runs the element of life—fresh well water—through the veins of the irrigation system. It pulls from a 1500-gallon water tank that is fed with nutrients and minerals. That water is recirculated for eight weeks before it’s fully flushed and is replenished.

“The plants are drinking about 20 gallons a day,” Gill said. “And we want to be environmentally conscious.” The piece of equipment that Gill is most excited about though, is the new outdoor heating system using wood and biomass that will replace the current propane heating. As I learn, propane produces a wet heat that suppresses the fragile plants’ growth, a no-go in hydroponic farming.

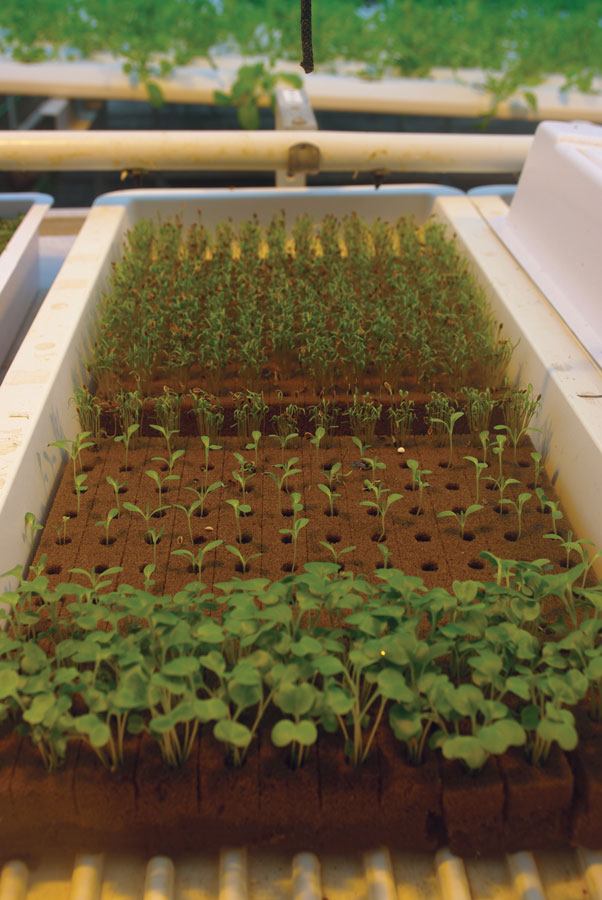

Various seedlings awaiting transplant Photo Credit: Jessica L. Fritz

From just a seed, to seedling stage, until becoming to a mature plant, the entire growth cycle of the variety of herbs and leafy greens happens in the greenhouse. A growth cycle is about six weeks in the summer and seven in the winter, using just water and the nutrient filling technique. Seeds are put into little cubes made of biodegradable foam and exposed to different settings of UV light. Once mature enough, the cubes with one small plant each, are set into a pipe-like structure called the channel. Each channel has 72 holes. Depending on the needs of the specific plant and its maturity size, a certain number of holes will remain empty between each plant to allow room for growth. Healthy growth leads to about 40 to 60 pounds of produce per table which is about 5 pounds per channel.

From plant growth to business growth, Pure Island Produce has been operational for about three years now though the technology being used in the greenhouse has a long track record, “AmHydro system is not new, they have about 25 years of experience,” Gill said about Pure Island Produce’s system.

Darren Gill with a hydroponic channel Photo Credit: Jessica L. Fritz

“It has been taking time, like any business, to get here but it’s pleasing,” Gill said. Climbing grocery prices and decreasing quality of fresh produce originally sparked the start of the business.

Today, it’s run in equal partnership by Dan and David Mitchell, known for their family-owned pizza business, Famous Peppers, and Gill. “Everyone [in this partnership] works full-time aside of this,” Gill said. Having grown up farming, he worked in the games industry and now works both with Pure Island Produce and as an IT contractor. Even the partners’ families lend a helping hand when needed.

Support also comes from the local food industry that Pure Island Produce is providing with fresh greens and herbs. The current clientele ranges from various restaurants in the Murphy Hospitality Group such as Sim’s Steakhouse, to the Olde Dublin Pub, to Harvest Wholesale, a restaurant supplier. Riverview Country Market has been carrying the produce from the get-go and is still the only retailer currently offering it direct-to-consumer.

And obviously, Famous Peppers’ pizzas (in both Montague and Charlottetown) are always being served with that touch of Pure Island Produce freshness, and its inherent taste of summer.

Fresh, flavourful herbs and greens year-round aren’t the only advantage of this farming style. “Chefs often tell us that we must have washed our produce really well as they cannot detect a chemical taste [from spraying it with pesticides]. But we don’t have to. We don’t get the pests usually transferred from soil. We get the good predators: spiders and ladybugs,” Gill said. So Pure Island Produce is just that—pure and untreated.

Long shelf life is another benefit, sold in the original cubes as a living system with its roots intact, it lasts weeks in a walk-in fridge. “Chefs love to be getting this type of product in November. We chat with different chefs and see how we can help them.”

That means what’s currently growing in the greenhouse—dill, basil, chives, parsley, Chinese kale, “Elegance” lettuce mix, broccolini, bok choy or swiss chard—might just be the arugula currently trialed for a new client, or whatever else your green dreams are made of.

- WHAT’S THE SCOOP? - June 1, 2019

- TARTNESS FROM EAST TO WEST - April 1, 2019

- ONE CLAN, ONE PLAN, ONE ORCHARD, ONE CIDER - February 1, 2019

- A TASTE OF SUMMER IN THE DEAD OF WINTER - December 1, 2018

- Retail Lessons Learned - October 28, 2018

- A DOWN HOME KITCHEN PARTY - September 25, 2018

- The Doors Are Open - June 24, 2018

- Sweet Success - June 1, 2018

- SEARCHING FOR CHOICE IN ISLAND STORES - May 1, 2018

- Zero Dollar Small Business Marketing 101-Maritime Marzipan - April 25, 2018